Progress toward decommissioning:Works to identify the plant status and toward fuel debris removal

In addition to decontamination and shield installation to improve PCV accessibility, technology was developed and data gathered as required to prepare to remove fuel debris (such as investigating and repairing PCV leak locations)

Status of Progress Points

(1) Development of remotely operated decontamination technology and methods in order to secure access to the building

- Decontamination methods are being examined in order to reduce the exposure of workers inside the building.

(2) Preparations for inspecting the inside of the PCV (identifying and repairing leaks, sampling surveys, etc.)

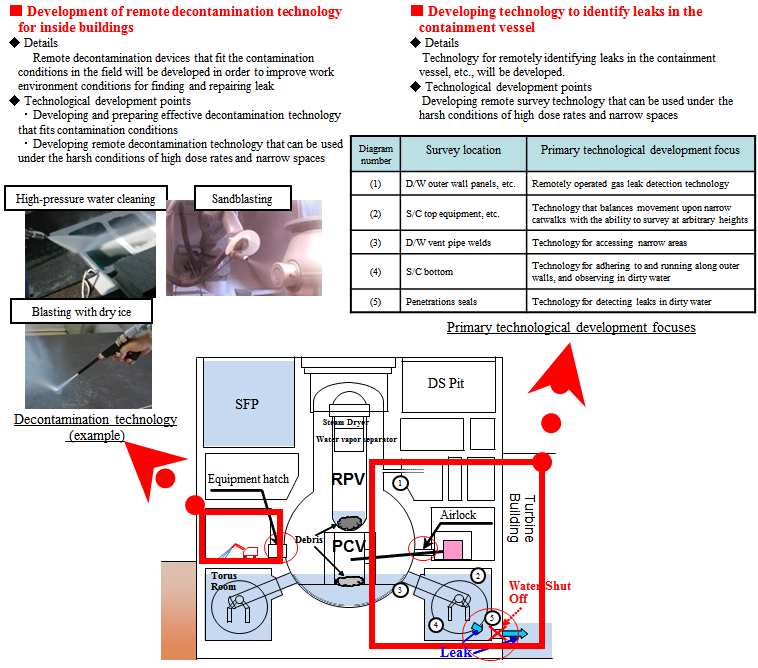

- Deliberations have begun on the development of a robot under the supervision of the remote technology task force in preparation for identifying and repairing PCV leaks.

- Surveys of the torus and the triangle corner inside the reactor building will be implemented in order to contribute to robot development.

(3) Ascertaining conditions inside the core by leveraging analysis codes, and fundamental research for ascertaining the characteristics of fuel debris

- Simulation analysis codes are being analyzed and being made more advanced in order to ascertain conditions inside the core.

- Fundamental research has begun on ways to ascertain debris characteristics in order to help with field debris removal/storage/processing/disposal.

Proposing plans for decontaminating the inside of the buildings and for reducing overall dose levels

- A survey of the degree of contamination inside reactor buildings has been conducted (dose rate survey/contamination sampling/analysis) and remote decontamination devices are being developed in accordance with the state of contamination.

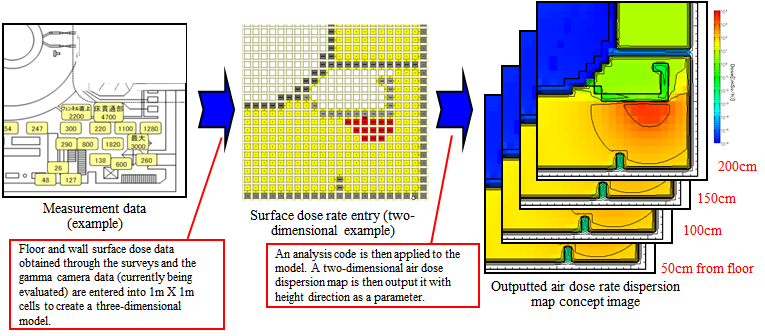

- A dose rate map for inside the building has been created using dose rate survey results and a decontamination plan is being created. The JAEA has been asked to perform a detailed analysis of the contamination samples and effective decontamination methods are being deliberated.

- Detailed plans that include decontamination/shielding/equipment removal are starting to be created in order to contribute to reducing dose levels inside the reactor buildings.

Dose dispersion map creation concept image

Identifying and repairing leaks within the containment vessel

- A suppression chamber (S/C) water level measurement robot fundamental technology development WG and underwater robot fundamental technology development WG has been established under the remote technology task force and deliberations have begun.

- A list of containment vessel boundary parts that include those areas that need to be subjected to a damage evaluation will be evaluated to determine whether or not damage was caused by a severe accident (earthquake, temperature, etc.) and the possibility of damage to each part will be determined. Upon doing this, areas that need to be surveyed will be extracted and methods for accessing the aforementioned areas will be examined.

- Existing technology has been examined and methods for designing and maintaining (stopping leaks) survey devices that can inspect envisioned leak locations are being deliberated.

- Robots are being developed perform work in high-dose areas. In order to solidify robot specifications, the triangle corner in the reactor building and the Torus will be surveyed and various data, such as radiation levels, the level of accumulated water and atmospheric temperature, etc., shall be sampled.

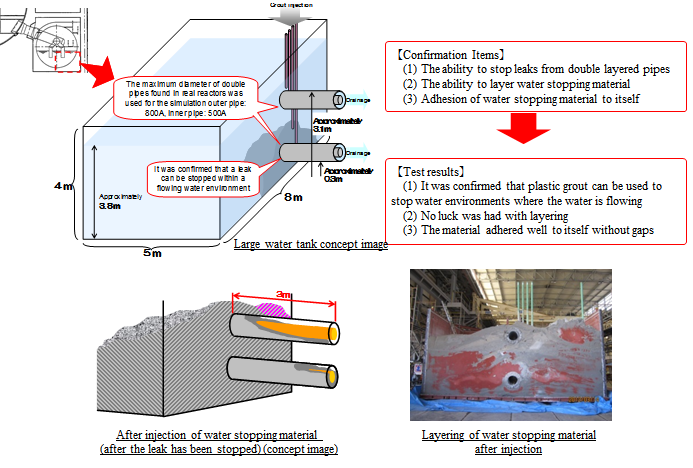

- Water tank tests were performed on materials for stopping water between buildings and the effectiveness of plastic grout was confirmed (March 2012).

Overview of water tank tests on water stopping material for between buildings

Contamination status survey and decontamination of Reactor Building Units 1 to 3

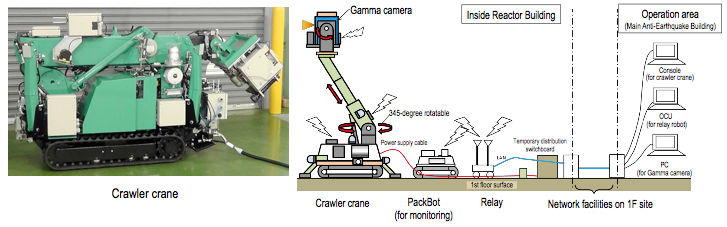

- To examine methods to reduce the radiation dose on the 2nd and 3rd floors of the Reactor Building Units 1 to 3, measurement of the radiation dose rates and investigation using gamma cameras with remote-control robots are underway on the 2nd and 3rd floors of Units 1 and 2, and the 2nd floor of Unit 3.

- To investigate areas significantly contributing to radiation dose rates (hot spots) on the 1st floor of the Reactor Building Units 1 to 3, an investigation using gamma cameras mounted on the remote-control robot (crawler crane) is underway in the upper areas of the relevant floors.

Remote-control robot to investigate the contamination status of 1st floor upper

Survey of the inside of the containment vessel in preparation for fuel debris extraction

- The development of a device for ascertaining the condition of fuel debris and the pedestal is being deliberated.

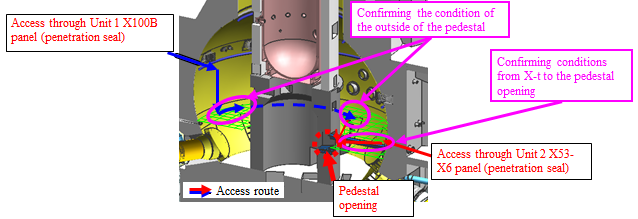

- The specifications of a device that can measure dose and temperature, and take photographs of the opening of the pedestal, etc., after being inserted through the penetration seals of the Unit 1 and Unit 2 containment vessels are being deliberated.

Pre-survey items and access routes (tentative)

Ascertaining and analyzing conditions inside the core

- Analysis and advancement of analysis code to simulate conditions inside the core were implemented.

- An international benchmark analysis project for Fukushima accident analysis was launched in cooperation with the OECD/NEA.

Preparations for ascertaining the characteristics of fuel debris and processing

- Assessing physical attributes of fuel debris that will impact the development of devices used for extracting it.

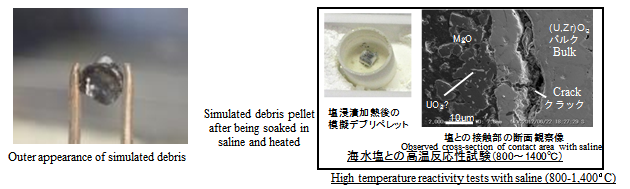

- Simulated debris was manufactured in order to obtain fundamental data regarding the temperature reactions with seawater salt.

- A processing scenario draft was created in regards to processing after fuel debris has been extracted (storage, processing, disposal, etc.) and the pros and cons of a part of the process (debris storage) were evaluated.

Future issues and the direction of countermeasures

Continual deliberation of mid-term issues regarding fuel debris extraction

- In order to extract fuel debris it is necessary to develop technology for surveying and making repairs under harsh environmental conditions, as well as collecting knowledge from within and outside Japan regards to ascertaining unknown conditions inside the core and the state and characteristics of fuel debris.

- In order to develop devices and equipment the technology catalog will be leveraged and a public appeal will be made for technology owned by private corporations and research institutions both within and outside of Japan.

- Through coordination with international agencies information will be disseminated from Japan and knowledge and experience in regard to developing difficult technology will be gathered.

- Further in the field investigation of existing technology will be conducted and feedback given to R&D aimed at developing technology for surveying and repairing leaks in the containment vessel and ascertaining of plant status as quickly as possible.

- Deliberation of alternative methods for flooding if containment vessel boundaries cannot be constructed.